Below is the painting guide I wrote up for the guys over at QCFGaming. After I posted some pics of my work, I guess they were happy with the results. They've tried to add this tot heir website, but it hasn't really worked that well. Since a few people have asked to see the guide, and I have to reference it on Part 5 of my building writeup and don't feel like rehashing anything, I just posted it here. Hope this helps somebody out there....

I’ve been asked to do a write up on my painting technique for QCFGaming. I feel so special! Before we begin, I need to touch on a few things. First, a lot of credit must go to Digital717 over on the SRK forums. His guide was what got me started on my paint job. You can find his info here:

MDF Mirror Finish Worklog

Second, consider both write-ups as guides, not etched in stone rules. I am by no means a professional (as some of the pictures will attest!), and I’m sure if you ask different people you’ll get different answers and have similar results. However you chose to go, as long as you have patience, you will have results you can be proud of. Make sure to read the entire guide, look at the bonus points, and decide what will work best for the finish you’re looking for. Now, onto the show….

Congratulations! You just got your QCFGaming case. While waiting for it to get shipped, you no doubt had visions in your head on how the stick will look. You open up the USPS box, dig thru the paper, and are presented with….a rather brown box. How in the world are you going to get that to look like the other custom cases you’ve seen? Fear not, we’re here to help.

First off, you’ll need to get your materials together. Some you may have around the house, some you may need to head to the local hardware or automotive supply store. You will need:

• A filler (wood filler, joint compound, spackle, Bondo, etc)

• Sandpaper (100, 180, 220, 320, 400, for dry sanding, 600, 1000, 1500, 2000 grit for wetsanding)

• Steel wool (000 and 0000 Grade)

• Rubbing Compound

• Polishing Compound

• Wax (optional)

• Spray paint (enamel or lacquer, either seems to work)

• Spray clear gloss (again, either enamel or lacquer)

• Tack cloth

• Terry cloth rags

• Spray Bottle

• Turpentine, mineral spirits, or other paint safe cleaner

• Rubber/latex gloves

• Dust mast or respirator

As we go along, I’ll explain what we’re using everything for. Let’s get to it!

Step 1- Prep the box

Have a look at your box. See all the fuzzy, unfinished edges where the parts join together and where the routed edges are? Those are the enemy. First off, when you hit them with the spray paint, they will show every joint line. Second, the unfinished edges of the MDF act like sponges on paint. Definitely not what you want. That’s where the filler comes in. What you want to do is spread a nice layer of filler along all the edges and joints until they aren’t visible. You don’t need to use too much. Once that’s dry, it’s time to sand it smooth. Grab the lowest grit sandpaper and sand it as level as you can. Try not to sand into the MDF. Once it’s sufficiently level, move to a higher grit of sandpaper (180 or 220 should do the trick) to get everything nice and smooth. When you run your finger across the spot where you used the filler, you want it to feel smooth and level, with very little peaks or valleys. You should not be able to feel the edge where the MDF stops and the filler begins. If you don’t, it will stick out like a sore thumb when the paint is sprayed on. Once you’re done, wipe the dust off with the tack cloth and use a rag and mineral spirits to remove any fine dust and fingerprints. Use gloves to keep the stuff off your hands.

Bonus Point - Box Prep

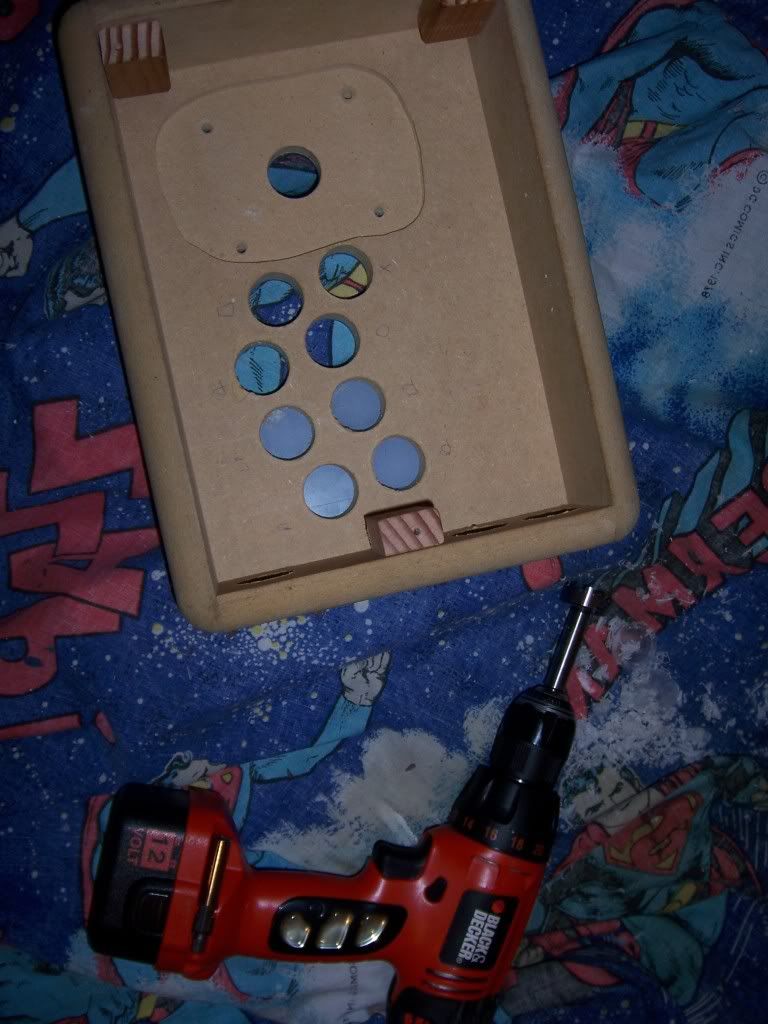

Here’s a tip for anybody with a HAPP style box. Since the joystick mounts from the bottom, you have to drill holes in the top panel and drop the screws in for the joystick. Some people don’t mind the screw heads showing, or use countersunk screws to get the screw head flush with the panel. Personally, I don’t want to see any screws, whether I’ve got art or plexiglass covering it or not. So, I picked up a #12 countersink bit like this:

Mark your holes and use the countersink bit to drill into the MDF so the screw heads are below the surface, like this:

Grab some wood glue or contractors glue and shoot some in the hole. Drop the screws in and use your filler to cover the holes. Then sand and smooth as before. Now, you have a nice, bolt free top that will look like a solid block when you’re done!

Step 2 – Priming and Sanding

Using primer on your box is very important. Not only will it provide a better surface for your paint to adhere to, but it fills and smoothes any imperfections in the MDF. The color of the primer doesn’t really matter (although if you’re painting the box black, using black primer can help you cheat in case of any screw ups when you’re sanding, as we’ll see later). Make sure your paint area is CLEAN and well ventilated. When using spray paint, spraying a number of light coats is always better than one heavy coat. We’re not doing graffiti! Grab your mask (you really don’t want to inhale this stuff too much), hold the can 10-12 inches from the box and spray in a straight line from end to end. Start spraying before you hit the edge of the box and stop spraying after you are completely off the other side. 2 or 3 light coats about 2-5 minutes apart should do. Then put the can down and walk away. Most likely the box will not have a full coating of paint and the MDF will show thru. That is fine! You will cover it with the subsequent layers. Let the paint dry per the directions on the primer (generally 30 minutes to an hour), then repeat the steps. After you’ve done this 3-4 times, you should have a pretty uniform coverage of paint. Have a look at the parts that you used your filler on. If you sanded them down well, you should notice very few, if any, high spots in the paint. If you do see them, go back with your 180 or 220 grit and smooth it out, then respray that area. It may be a pain to do, but it will look so much better once the paint goes on. Once it’s done, let it sit for 24 hours to dry. If it’s cold or humid, you may need to wait a bit longer to dry.

Next up: sanding. We want to sand the primer relatively smooth so the paint has a nice even surface to stick to. Grab some 220 or 320 grit (and your mask!) and sand down the primer. You can use a sanding block or wrap the sandpaper around a small block of wood so you can put even pressure on the paint. Be very careful around the edges of the box! It is extremely easy to sand thru the paint or primer if you’re not careful. I like to use 3M flexible finish sandpaper, which is really good on any rounded edges. The primer also doesn’t seem to build up nearly as much. If you do sand thru the primer, spray the part with a few light coats, let it dry a few hours, then lightly resand and you should be fine. Finish up with a light sanding using 400 grit sandpaper. Once everything looks and feels nice and smooth, wipe with the tack cloth and use the mineral spirits to clean everything. You should look something like this:

Done! Now it’s time for some paint

Bonus Points - Primer

Some have asked whether or not brushable primer would work for this application. To be honest, I haven’t really tried it, although I have some from patching drywall around the house. My first thought would be maybe, but it may be more work than it’s worth. I wouldn’t attempt to use a brush to apply it, as sanding the brush strokes out would be a pain. A small, foam trim roller may well do the trick, but I’m not sure how the primer would set up once it dried. If you choose to go that route, just be sure to sand it smooth and clean it as mentioned above.

A Word on Enamel Paint vs. Lacquer Paint

You may or may not have noticed when you got your paint that you have the choice between enamel paint and lacquer paint. Either will ultimately do the job, but with slightly different handling directions. The biggest difference in the two are the solvent or "carrier" of the paint. Lacquer paint uses lacquer thinner and enamel paint uses paint thinner. One of the advantages of lacquer paint is that it dries more quickly than enamel and does not have a re-coat window (a time when a subsequent coat must be reapplied). With lacquer, you can spray the next coat once it is dry. With an enamel, you generally have a 1-2 hour time period in which you must spray the next coat, or you will need to wait for the paint to cure, which can take 3-5 days, depending on your brand of paint. Check the instructions on your paint can and be sure to follow those. An advantage of enamel over lacquer is that enamel can be used over either enamel or lacquer paint. The paint thinning solvent will not affect the dried layers of paint. Lacquer, on the other hand, can eat thru or wrinkle enamel paint because of the lacquer thinner it uses. It’s also smellier and a bit more toxic than enamel (not that you want to go sniffing either, mind you…). In short, enamel plays nice with anything, but let lacquer stick with lacquer.

Step 3 – Painting and Sanding

Here is where the rubber meets the road, as it were. This will require patience more than anything else. It may seem tedious, but if you get it right your finish will look fantastic. First off, grab your mask and the paint. Just like with the primer, you want 2-3 light coats, wait 2-5 minutes, then 2-3 more light coats. Afterward, put the can down and let it dry 45 minutes to an hour and repeat. How many coats? Hard to say. Once you have a nice, even coverage on the box, you should be good to go. However, I like to add a few more coats on just to give me some padding in case anything goes wrong with the sanding. Again, let it dry at least 24 hours before touching it. Before you turn in for the day, soak the wetsanding paper (the 600-2000 grit stuff) in a bucket of water with a few drops of dishwashing liquid for the same 24 hour period.

Once it’s dry, the sanding can begin. Get your mask and start with the 400 grit like you did with the primer. Careful on the edges, lest you cut thru the paint. Once that’s nice and smooth, clean it with the mineral spirits and let that dry. Now comes the fun part. Get the 600 grit paper out of the bucket and wrap it around your sanding block. Then, very carefully, and with very little pressure, start sanding the paint. Let the sandpaper do the work, making sure to spray down the sandpaper every 30-45 seconds to keep it wet. The soapy water solution keeps the sandpaper lubricated and rinses the paint off the sandpaper, keeping it from loading up. The sandpaper should glide smoothly across the surface of the paint without grabbing. If you start grabbing, stop, spray down the paper, and continue. Sand a small area at a time, making sure to wipe the area dry to check your progress and to keep standing water off the box. Again, be extremely careful around the edges, as one swipe will take the paint off. It may be easier to very lightly go over the edge with your hand, letting the paper do the work. However, if the edges look good, you may be able not to even bother with them too much. Once completed, wipe everything down with mineral spirits. Repeat the process with the 1000, 1500, and 2000 grit sandpaper. At this point, the paint should be even and look white and dull, as if somebody spilled milk or baby powder on it and didn’t quite clean it all up. This is absolutely what you are looking for. The next 2 steps will take care of it. Now, give yourself a break before we continue on.

Bonus Points – Sanding Alternatives

At this point I should point out a few differing opinions on sanding your finish. First off is the wet sanding / dry sanding debate. Some say you can achieve similar (or the same) results by dry sanding with the higher grit sandpaper. Some advantages to dry sanding are you don’t have messy water drips everywhere and it is easier to see what you’re doing and what needs to be sanded more. The disadvantages include the sandpaper loading up with paint, thus reducing it’s effectiveness and requiring the use of more sandpaper. Also, you end up trading a wet mess for a dry, dusty mess. With either technique, be sure to use light, even pressure and be careful around the corners!

Instead of wetsanding with 600 and 1000 paper, some have tried using steel wool. Steel wool is popular in polishing metal and wood. For our application, steel wool can work as well, up to a point . Steel wool is much more malleable than sandpaper, thus easier to go over rounded corners with. It also leaves a very nice, even finish on the paint. You could transition from 000 grade to 0000 grade steel wool, much like transitioning to a higher grit of sandpaper. 0000 grade steel wool is roughly as abrasive as 1000 grit sandpaper. Depending on the level of gloss you are looking for, stopping at either 1000 grit sandpaper or 0000 grade wool is fine. But if you’re looking for a super shiny, almost mirror finish, continue on with the 1500 and 2000 grit sandpaper.

Step 4 – Clearcoat

As Yogi Berra once said, the next step will feel like ‘déjà vu all over again’. Get your mask, grab the clear gloss paint and start spraying the box just like you sprayed the primer and paint before – 2-3 coats nice light, even coats, 2-5 minutes in between each. Let that dry 45 minutes to an hour, and repeat. Once the coats are on, let it dry for 24 hours. As you can see, the milky white finish now looks nice and shiny. Now, if the paint looks nice enough to you already, or you’re tired and ready to move on, have at it. If you want that super glossy, wet mirror finish, repeat the sanding process as above. Whether you wetsand or drysand, use sandpaper or steel wool, make sure to finish with the 2000 grit paper! Again, when you finish, the surface should have the even, dull dry look to it, like a slightly shinier version of the paint after you finished sanding it. The finish should also feel as smooth as glass if you run your fingers across it . Clean it with the mineral spirits and take a break. The last step will require some elbow grease.

Step 5 – Compound and Polish

Have you ever had to wash and wax your car before? If so, this last step should be a piece of cake. If not, just remember what Mr. Miogi told Daniel-san – ‘Wax on, Wax off’. Think of the compounds as liquid sandpaper: a very high grit abrasive that will sand and polish the paint like stones in a rock tumbler. Start with the rubbing compound and a terry cloth. Follow the directions on the bottle. Pour some of the rubbing compound on your rag and work it into the paint. As you do, you should see the color come back in with a pretty high shine. Wipe off the residue with a clean terry cloth per the directions. When you’re done, you should have a pretty deep, rich color, albeit with a bunch of swirl marks. That’s what the polishing compound is for. Follow the instructions on the package and do the same thing. Now you should have a very shiny, almost streak and swirl free finish that looks like it came from the factory. Hold it up to the light and admire your work. Pat yourself on the back, good man (or woman) for a job well done.

Bonus Tip – Polish and Wax

If you really want to go all out, or just like the whole wax on, wax off deal, you can add a coat of polish and wax. Polish is less abrasive than either the rubbing or polishing compounds, which are mainly used for finishing the paint finish. A polish or glaze will provide that extra sheen and smoothness. Your local auto parts store has a pretty good selection. I like Meguiars Deep Crystal System Polish or their Mirror Glaze line of products. Mothers and Eagle One also work well. Now, wax and polish are two different things for two different purposes. Polish adds shine, wax adds protection. So for that added layer of protection for your shiny new finish, you may want to add a wax. However, you need to wait 30 days for the paint to fully cure (curing is different from drying!) before waxing your paint. You may need to disassemble your pride and joy unless you want to get was residue off the buttons, but if you wish to go all out, that’s your choice. The added bonus: you now have products to shine your car to a finish as nice as your stick!

That’s it people. Hopefully this guide will help you achieve a finish you can be proud of while you show off your latest creation. Remember, these are just suggestions, not rules. As they say, your mileage may vary. Thanks goes to the guys at QCF (Lucky Day and Satek), Digital717 for the original worklog and the inspiration for this guide, Toodles, ShinJ, Purplearms, Beneco74, Gummouned, Lizard Lick, GamingNow, and everybody else on he SRK forums that pushed me to building my first stick in the first place. If you have any questions, comments, or things I should chance, feel free to contact me at spenzalii@att.net

Enjoy!

Spenzalii