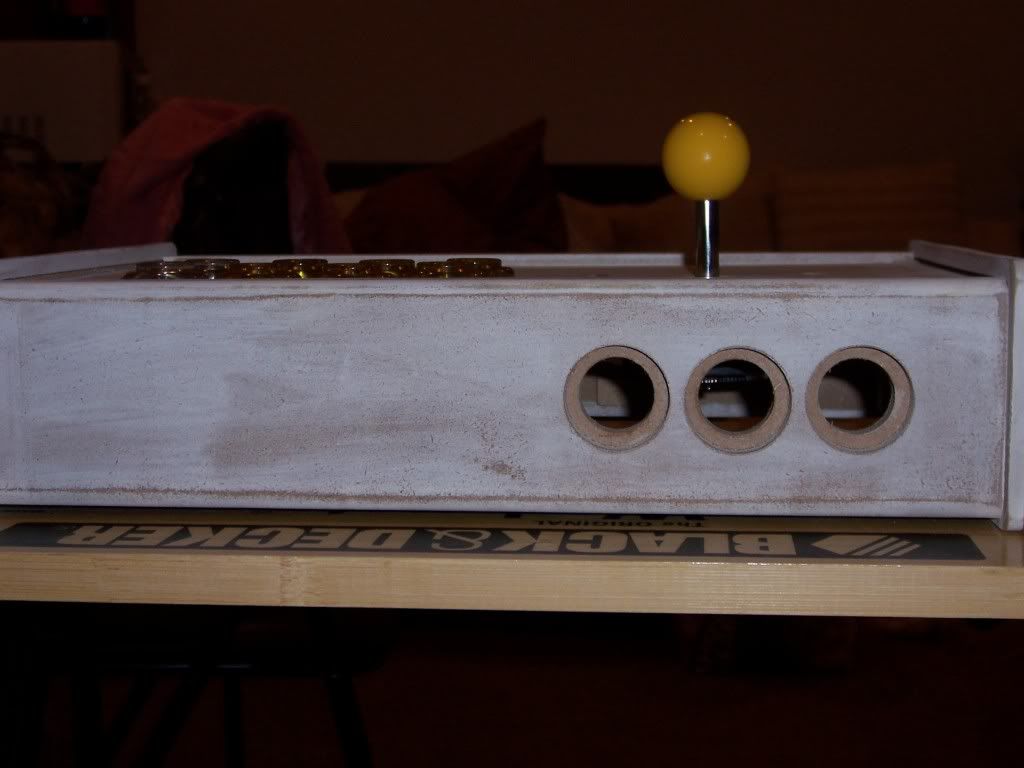

Something's missing from those buttons....

The buttons for the start, select, and home were on the rear of the case. While it’s easier to hit them on the side of the case, like El Kabong’s setup, it does make more sense from a layout standpoint when you start wiring up the buttons and pcbs. Since you have to reach to the back of the case, it also makes sure that you only hit any of those buttons when you really mean to.

That primer makes the case look ashy...

The holes were drilled out for Sanwa or Semeitsu 24mm buttons (Happ/iL doesn’t make any that size). However, when I put one of them in the hole to see how it fit, I didn’t like it. There was too much wood exposed around the rim of the button, and the holes themselves seemed too deep for such a small button. So I rummaged thru my assortment of spare parts from my last project to see what I could use as an alternative. I had picked up a lighted Happ button designed to be used in video poker games and the like just to see how it felt and if it were feasible to use as buttons on another project. It dropped in the hole without too much fuss, and didn’t have as much exposed wood around the rim. However, the button protruded much farther into the case than the Sanwa button I had, which would complicate routing the wires once everything was installed. I then grabbed the 30mm Semeitsu button I never used to get an idea how that would look. It looked like the 30mm would have the least amount of exposed wood, if any. However, I would have to widen the holes to make the buttons fit.

Like Goldilocks and the 3 bears...

That's a pretty big difference

So, it was time to break out the tools. First, I put the case in my mini workbench/vise to hold the case steady. Next, I grabbed my round wood rasp, which is like an aggressive, heavy duty file. Rasps are great if you need to quickly remove or shape a piece of wood. Unlike a file, however, you only use the rasp in one direction, pushing it down or forward thru the material, instead of back and forth like a file, which would ruin the rasp. I made a few passes all the way around the hole, testing to see if it were wide enough every few passes (remember, you can take the material off, but you can’t put it back!). After about 15 minutes, I had the clearance I needed. The 30mm button filled the hole nicely and still remained below the surface of the case, making it harder to accidentally brush against it and hit the button.

Hand tools are great!

The bad thing, however, is now I had to figure out what color 30mm buttons I needed to buy. Oh well. Such is the nature of a custom stick. You could start out in one direction and end up with something completely different by time you are done.

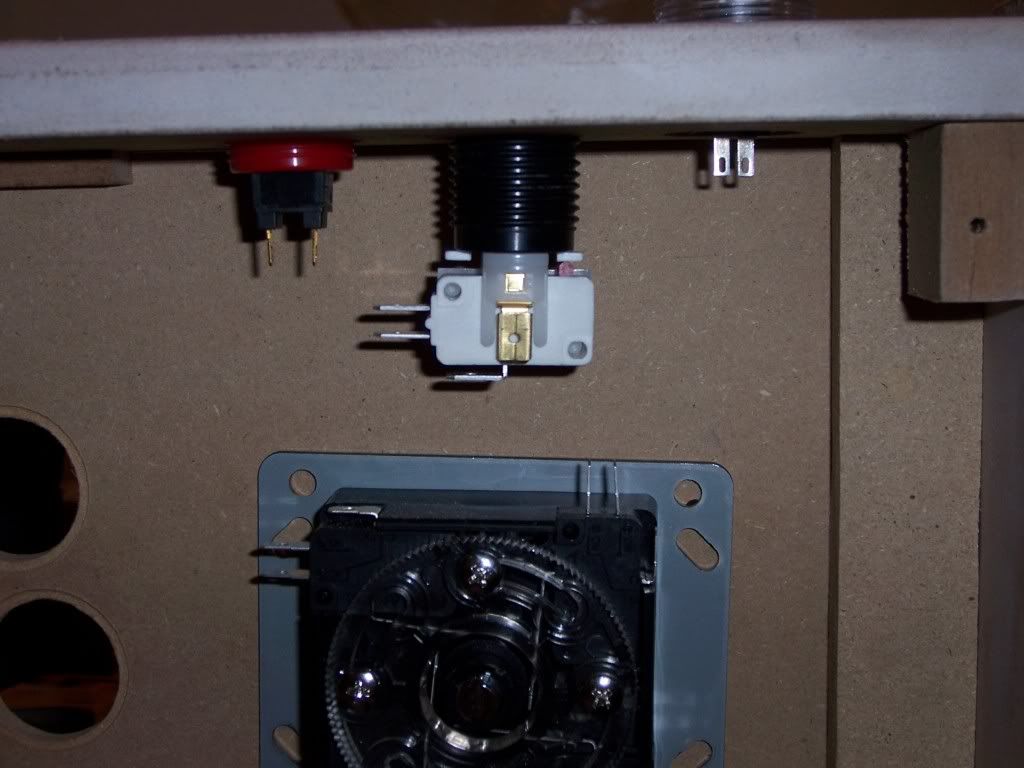

After getting the buttons sorted out, it was time to figure out what I was going to do with the switches. At first glance, the slide switches looked like they would be easier to install. But the more I looked at the case, the less likely they would work the way I wanted. The simple solution would be to mount them on an edge of the case, with the switch just slightly protruding from the bottom. Somehow that didn’t really appeal to me that much, as I feared the wiring to the switches would be a bit messy and I didn’t want the switch to be accidentally moved while playing with the case in your lap. Mounting it to the back of the case along with the start button was an option, but there wasn’t a clear way to mount the switches anywhere near flush to the back of the case. So, I put those to the side and got the rocker switches. While much bigger than the slide switches, if I mounted them on the back of the case they would have a more integrated look, whereas the exposed slide switches would look like the back of an old Atari 2600. In order to have the switches recessed similar to the buttons, I would need to chisel out a portion of the case. So, I traced a template for the two switches in a stacked position and placed it on the case. Next, I took my chisel and cut out the space. Since I’m no carpenter, you can watch this video to see how to use a chisel (a useful tool to have, I must say…)

Since I was working with what appeared to be MDF and not poplar or maple, it wasn’t very hard to cut the space out. In fact, I didn’t really need a mallet or hammer on anything other than outlining the edges. After about 20 minutes, I had the rough cut done.

It will look much neater once primed and painted

Once I had the space deep enough to my liking, I put the case back in the vise and made the holes for the body of the switch to go inside the case. I used a combination of a drill bit, my dremel and the rasp to widen and shape the holes. Afterward, I dropped the switches in to see how they looked. Success…

I wonder if I can paint them yellow...

Not exactly even, but it gets the job done

In retrospect, I probably could have chiseled the front side of the case a little deeper, so that the switches were recessed more, which may have givin the needed clearance for the retaining nuts without having to work on the inside of the case. But, what's done is done. I still needed to cut the space for the USB adaptor, but at this point it hadn't come in the mail yet. Who's have thought it took so long to ship something that small from Hong Kong? No matter. The next stage of the project would take up more time than I ever expected.

No comments:

Post a Comment